Well it really is not a cost saving exercise to chose COG/NP0 ceramics. It is to do with distortion harmonics being vanishingly small (see my Bateman quote above), and the fact that the are small. There is a powerful rationale for keeping phono stages compact. Physically large parts (like Teflon capacitors) are much more susceptible to hum and RF pickup; and a distinct possibility that parasitic coupling to circuit board traces could put whatever opamp or discrete opamp you're using into RF or audio oscillation.

In my experience, Teflon caps Take forever to break in, but sound very detailed and clean. I like'em!

400 hours is what CJ recommends... I agree with them.

Sure... though this is by measurement and that I also take seriously. My interest is in pushing the sonic limits. I am currently using a largish 22nF teflon in a phono stage open to the environment that I doubt would have worse measured distortion than a COG/NPO. The network currently has detectable line frequency artifacts at high gain settings seemingly the result of using this physically large capacitor, though these are expected to disappear when enclosed and with separated power supply. DC offset shifting can also be a sign of RF pickup and susceptibility that I am looking for to avoid.Well it really is not a cost saving exercise to chose COG/NP0 ceramics. It is to do with distortion harmonics being vanishingly small (see my Bateman quote above), and the fact that the are small. There is a powerful rationale for keeping phono stages compact. Physically large parts (like Teflon capacitors) are much more susceptible to hum and RF pickup; and a distinct possibility that parasitic coupling to circuit board traces could put whatever opamp or discrete opamp you're using into RF or audio oscillation.

I agree that considerable care is required in network design to mitigate parasitic coupling and the suppression of RF artifacts and oscillation. This is the reason for a battery powered head amplifier in a separated isolated box. Turning the head amplifier on/off does not change the 60Hz line artifacts but does raise the noise floor, oddly at higher frequencies than the subsequent RIAA gain stage network with the head amp switched off.

There is often a balancing act between networks that create greater intimacy and involvement with the artists in a recording and the noise level of the network. At the moment the balance is acceptable to me, though I am still looking not to be forced to make such compromises. Good phono reproduction often flows through the ticks, pops and noise on the vinyl itself as well, seemingly to diminish them.

Just found my Component Research 0.22uF teflons from way back in the 1980's I believe. These were rated 10% but luckily both measure 0.224 uF. Should be less than 0.5%. I must have purchased a matched pair back in the day. Unfortunately they are huge at 600VDC. Anyone have any experience with these caps?

The Component Research 0.22uF teflons didn't work out. Sounded full bodied but far too lossy sounding in the not too upper registers, being also too lifeless. I suspect there was too much dielectric given the voltage rating and also required too much current from the driver stages.

I switched to using some paralleled 100nF (measuring 198nF) COG/NPO received from Digikey. Things didn't improve overall until using a singular 100nF in the network (and redoing the poles). This still wasn't optimal in relation to having tried the 0.022uF Russian teflons with far greater spatiality, though the weight was better. Using the COG/NPO's the presentation seemed accurate, though wasn't conducive to pulling me into the music and forgetting about the electronics. Perhaps the COG's are revealing the limitations of the surrounding electronics though.

The plan is to try the 100nF COG's in series (50nF) against paralleled Russians 0.022uF (44nF). I seem to recall that 0.047uF or thereabouts was a fairly common value in the RIAA.

I switched to using some paralleled 100nF (measuring 198nF) COG/NPO received from Digikey. Things didn't improve overall until using a singular 100nF in the network (and redoing the poles). This still wasn't optimal in relation to having tried the 0.022uF Russian teflons with far greater spatiality, though the weight was better. Using the COG/NPO's the presentation seemed accurate, though wasn't conducive to pulling me into the music and forgetting about the electronics. Perhaps the COG's are revealing the limitations of the surrounding electronics though.

The plan is to try the 100nF COG's in series (50nF) against paralleled Russians 0.022uF (44nF). I seem to recall that 0.047uF or thereabouts was a fairly common value in the RIAA.

The capacitance values were first measured using a YFE YF-150 capacitance meter with alleged 0.5% accuracy. Then a calculator is used to obtain a resistance value with subsequent physical testing to fine tune the poles by modifying the resistance.

I have tested paralleled 100nF COG's each measuring 99.0 nF for 198nF. The network was then modified to use a single 99nF COG, as sonically preferred to the paralleled pair. Perhaps the next is to series connect them to obtain 49.5nF. If this works I want to compare this to some 47nF teflons or perhaps back to the original 22nF teflons. Although COG's have low distortion and pickup it isn't clear if they are preferable to teflons even though it is hoped they are.

I have tested paralleled 100nF COG's each measuring 99.0 nF for 198nF. The network was then modified to use a single 99nF COG, as sonically preferred to the paralleled pair. Perhaps the next is to series connect them to obtain 49.5nF. If this works I want to compare this to some 47nF teflons or perhaps back to the original 22nF teflons. Although COG's have low distortion and pickup it isn't clear if they are preferable to teflons even though it is hoped they are.

Agree that spending 400 hours mentally (or is it verbally? 🤔) repeating the Mantra "these caps sound good ... these caps sound good ..." must eventually convince anybody that some caps sound better than others ... whatever that means .....400 hours is what CJ recommends... I agree with them.

I never ever heard the sound made by a capacitor, even in a very silent room, but maybe my heart beats too loud and masks it, who knows?

I have, when I used only ceramic X5R capacitors for decoupling an LM317 output. The LM317 sometimes oscillated at a few kilohertz and the piezoelectric capacitors made the corresponding beeping sound. They went silent and remained silent after I connected a run-of-the-mill electrolytic capacitor in parallel with the X5R capacitors.

It's never 'just' a capacitor. A more accurate model always has a network with inductors in it as well.

Are foil caps really that great? I take it the teflon is super expensive, but the Al2O3 oxidation on the surface of the Al foil is free of charge? 😂 That would be like a big ceramic capacitor in series with the teflon, or maybe a very small one in parallel. So, +1 for metallized film, assuming oxygen never migrates through the plastic, though it probably does over time.

Are foil caps really that great? I take it the teflon is super expensive, but the Al2O3 oxidation on the surface of the Al foil is free of charge? 😂 That would be like a big ceramic capacitor in series with the teflon, or maybe a very small one in parallel. So, +1 for metallized film, assuming oxygen never migrates through the plastic, though it probably does over time.

It is probably somewhere in this thread, but if you are using a feedback network calculation of component values is non-trivial. The landmark description of RIAA is S. Lipshitz, “On RIAA Equalization Networks,” JAES, Vol. 27 #6, June 1979, pp. 458–481. Still copyright by JAES, although there is an OCR version here https://pearl-hifi.com/06_Lit_Archi...s/Lipschitz_Stanley/Lipshitz_on_RIAA_JAES.pdf with all the normally embedded diagrams at the back.The capacitance values were first measured using a YFE YF-150 capacitance meter with alleged 0.5% accuracy. Then a calculator is used to obtain a resistance value with subsequent physical testing to fine tune the poles by modifying the resistance.

I have tested paralleled 100nF COG's each measuring 99.0 nF for 198nF. The network was then modified to use a single 99nF COG, as sonically preferred to the paralleled pair. Perhaps the next is to series connect them to obtain 49.5nF. If this works I want to compare this to some 47nF teflons or perhaps back to the original 22nF teflons. Although COG's have low distortion and pickup it isn't clear if they are preferable to teflons even though it is hoped they are.

I use one of these to measure capacitance values at audio frequencies https://www.ietlabs.com/pdf/Datasheets/1620.pdf . The internal capacitance standards are air capacitors made from super-invar with quartz insulators in a sealed and dry nitrogen filled box. I trust it completely.

One sobering test is to slightly warm a capacitor under test by putting your hand near the capacitor. COG, polystyrene and other low K capacitors change not at all, or only by a few parts in 10^6. Polyester, and high K ceramics change value dramatically.

Last edited:

I am considering the following teflon caps for the 50/500 portion of the RIAA network. Does anyone have any experience with these or lower values?

https://solen.ca/en/products/solen-...ors-s3q330n-0_33uf-1000v-teflon-film-tin-foil

Silver Mica 1% 500V would be fine for low RIAA values, and possibly cheaper.

T

Absolutely - has the compact size, precision and stability needed for a RIAA network. PTFE capacitors are much more expensive, a LOT bulkier and really only typically used in high temperature applications not suited for other dielectrics.Silver Mica 1% 500V would be fine for low RIAA values, and possibly cheaper.

I've just tested a 1000pF silver mica on my GR bridge. It measured 986.93pF (-3.1%) with a dissipation factor of 0.000833 at 1kHz. The -3% tolerance is fine for that particular part since it has a nominal tolerance of 5%.

There is no discernable change at an .01pF level when warming the part with my hand.

That is about as close to perfect audio frequency range as a capacitor gets.

There is no discernable change at an .01pF level when warming the part with my hand.

That is about as close to perfect audio frequency range as a capacitor gets.

I believe Van Alstine was a fan of using silver mica's for compensation in his amps. I have some lying around, probably close to that value, and could try one in the 2122 Hz pole for an experiment.

It is never absolute as to the cause of sonic variants, hence suggesting that one capacitor is better than another (assuming one is not dillusional about the perceived differences) can be problematic in not considering the network in which it is applied. A case in point is that adding resistance in series with the 2122 Hz capacitor in the feedback path substantially alters the sonics, seemingly a function of feedback stability and margins. This can also have a lot to do with the extent of loop disturbances related to RFI present when stability is pushed to the limit in order to reduce harmonic distortions.

It is never absolute as to the cause of sonic variants, hence suggesting that one capacitor is better than another (assuming one is not dillusional about the perceived differences) can be problematic in not considering the network in which it is applied. A case in point is that adding resistance in series with the 2122 Hz capacitor in the feedback path substantially alters the sonics, seemingly a function of feedback stability and margins. This can also have a lot to do with the extent of loop disturbances related to RFI present when stability is pushed to the limit in order to reduce harmonic distortions.

Of course it does. It adds a shelf to the HF response.adding resistance in series with the 2122 Hz capacitor in the feedback path substantially alters the sonics

As we are dealing with RIAA capacitors, I think that rather than the technology of the cap by itself, the perfect adjustment of the value is more important...

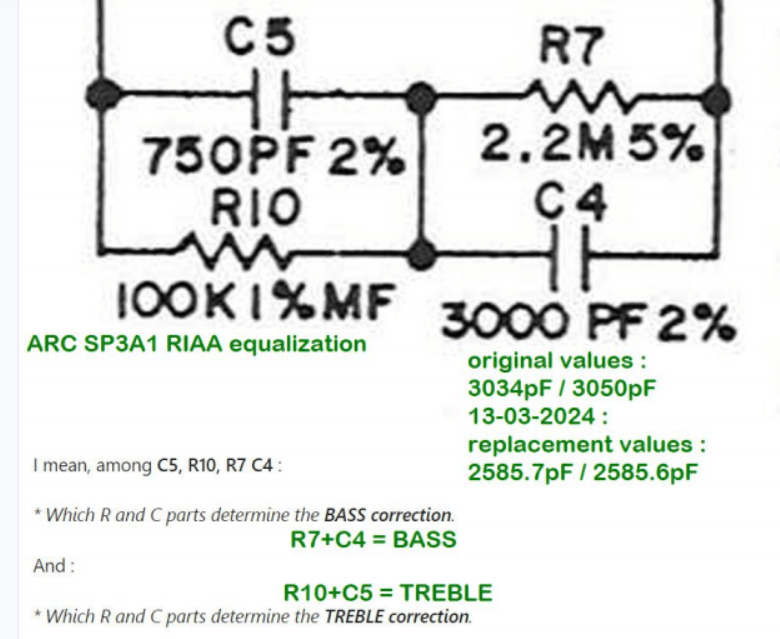

Here are the corrections that I made during the restoration of my Audio Research SP3A1 preamplifier - it concerns C4, which has been value selected and matched :

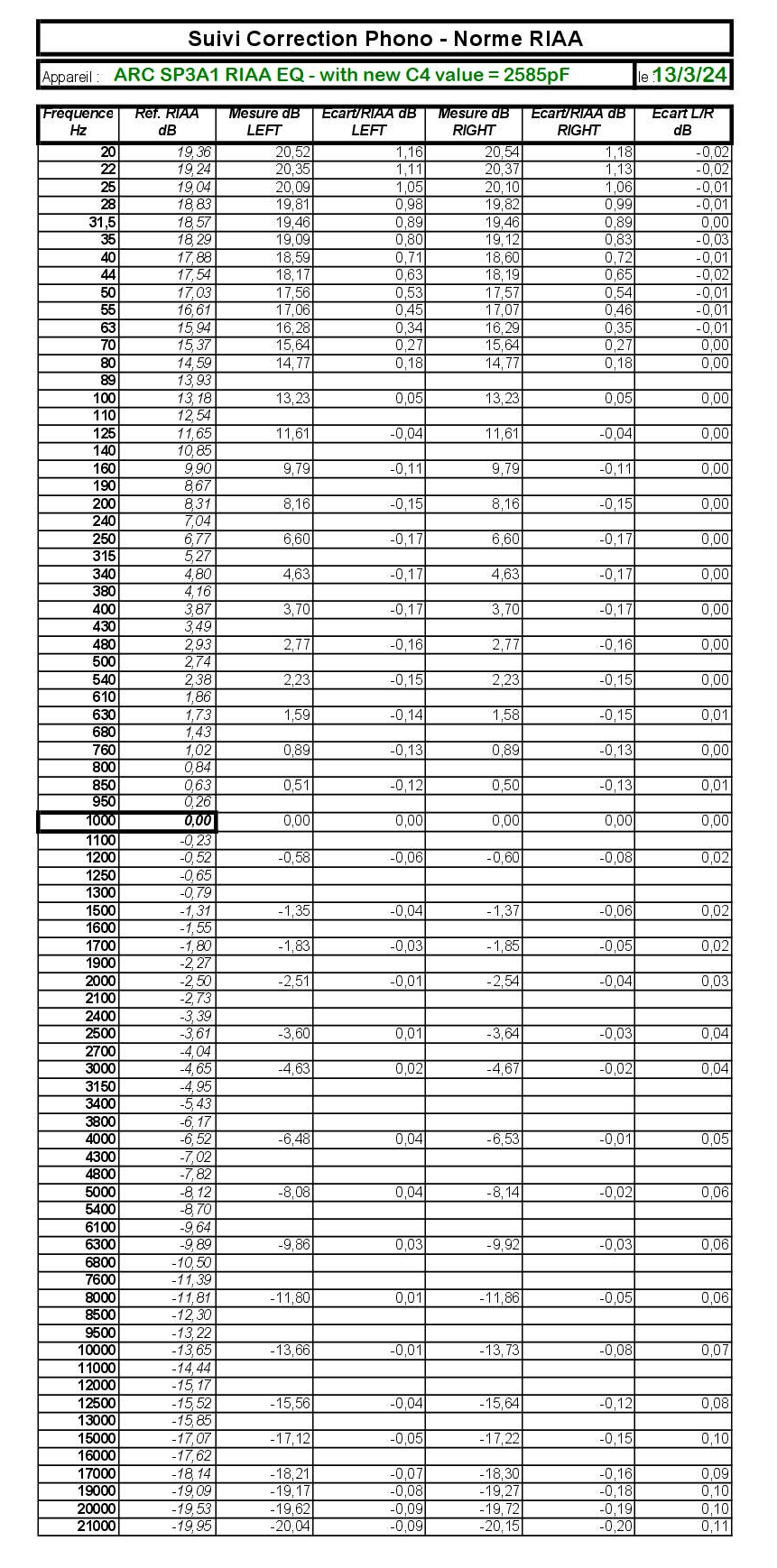

And here is the RIAA compensation obtained - All values in dB in the table below :

Aw ! Translation of the French terms, sorry...

Ref. RIAA = values according to the RIAA "extended" norm.

Mesure dB = measurement made by me on the modified preamp.

Ecart/RIAA = gap between the RIAA reference chart.

Ecart L/R = gap between L and R measured channels.

T

Here are the corrections that I made during the restoration of my Audio Research SP3A1 preamplifier - it concerns C4, which has been value selected and matched :

And here is the RIAA compensation obtained - All values in dB in the table below :

Aw ! Translation of the French terms, sorry...

Ref. RIAA = values according to the RIAA "extended" norm.

Mesure dB = measurement made by me on the modified preamp.

Ecart/RIAA = gap between the RIAA reference chart.

Ecart L/R = gap between L and R measured channels.

T

I have, when I used only ceramic X5R capacitors for decoupling an LM317 output. The LM317 sometimes oscillated at a few kilohertz and the piezoelectric capacitors made the corresponding beeping sound. They went silent and remained silent after I connected a run-of-the-mill electrolytic capacitor in parallel with the X5R capacitors.

Not just X5R's are microphonic. At one stage in the prehistoric past, I developed a supermarket security gate. The amplifier that fed the gate coils was class D - itself quite a radical choice in the mid 80s.

So it needed an output filter. I chose a polypropylene capacitor as part of the filter, and was greeted by a god awful warbling. The detailed construction of that particular capacitor had a loose section of windings at each end. Aha - so let's try an audio capacitor instead. A Kimber Kap (now discontinued). Dead silent. The critical difference was the tightness of the winding.

Of course, the audio capacitors were far too expensive for a commercial security gate. But I found that Roderstein axial polypropylene caps were almost identical in quietness, and cheap. Since taken over by Vishay in their quest to acquire any passive component company.

- Home

- Source & Line

- Analogue Source

- Teflon caps for RIAA?