Recently acquired a mid-80s Sota Sapphire that’s in decent shape but in need of some TLC. The motor and platter spin and the overall condition looks good, but before I fire it up with the platter on the belt I wanted to check the platter bearing.

Seems easy enough to get the platter off of the plinth, removing one bolt after tightening the bearing lockout/transport screws. From there I’ll be in unknown territory since it’s impossible to see what the next steps will be given the construction of the table.

Any guidance or direction from those who have restored their Sota Sapphire tables would be most welcome. Thanks.

Seems easy enough to get the platter off of the plinth, removing one bolt after tightening the bearing lockout/transport screws. From there I’ll be in unknown territory since it’s impossible to see what the next steps will be given the construction of the table.

Any guidance or direction from those who have restored their Sota Sapphire tables would be most welcome. Thanks.

With the small plate removed you can pull the platter off and run your finger nail to check for any ridge worn into the shaft

Visual wear is acceptable but anything you can feel is wornout.

Inspect the sapphire block for its contact patch and if a pit has started, it will only get worse and is toast

Be careful of dropping the shaft onto the sapphire disc

Cleanout the bushing well bushings and put in new oil. SOTA used 2 drops of Tuffoil and is the maximum absorption the bushings will

accept since you have an inverted bearing

Visual wear is acceptable but anything you can feel is wornout.

Inspect the sapphire block for its contact patch and if a pit has started, it will only get worse and is toast

Be careful of dropping the shaft onto the sapphire disc

Cleanout the bushing well bushings and put in new oil. SOTA used 2 drops of Tuffoil and is the maximum absorption the bushings will

accept since you have an inverted bearing

Pat’s Audio (ebay seller) used to offer replacement sapphire thrusts for damaged ones - but you’ll need to measure to be sure they fit. Alternatively, you can send the platter and bearing assy. to Sota for a rebuild. I believe they offer a “magnetic’ bearing upgrade as well..

I bought a mid '80s Star Sapphire with vacuum on Ebay around 2000, and almost immediately made a new plinth for it and replaced all of the suspension. The original golden oak plinth was so peak '80s that it had to go. The plinth I built was bleached wenge with finger jointed corners and clean chamfers instead of quarter round corners. I don't have any really good pictures, but here's my older son thinking "WTF dad?' around 2012.

And then in 2017 with the original vacuum pump seals dried out and failing and after making some custom parts for a new TT manufacturer I got a wild hair to do a major re-work. The new table was going to lose the suspended sub-chassis and be a very high mass rigid deck.

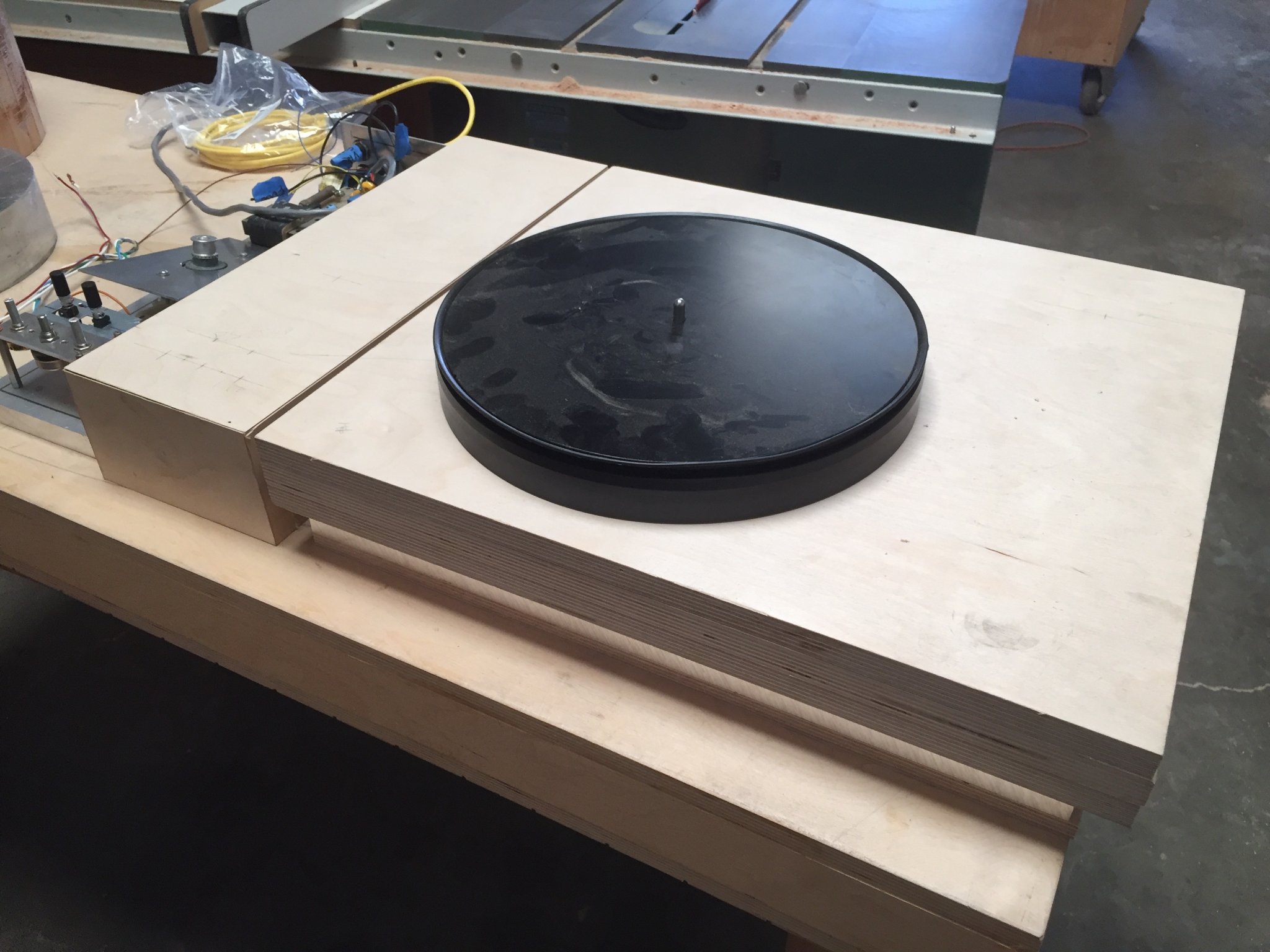

This happened:

I found a German company making a similar diaphragm type vacuum pump that was about twice the power of the original and decided on a heavy plinth with the platter, a separate module that would have the motor, power supply and controls with a very heavy vacuum module that could be placed way from everything else for the best isolation. The platter section is stacked Baltic Birch ply laminated to a 1" thick 6061 aluminum plate that the bearing would mount to.

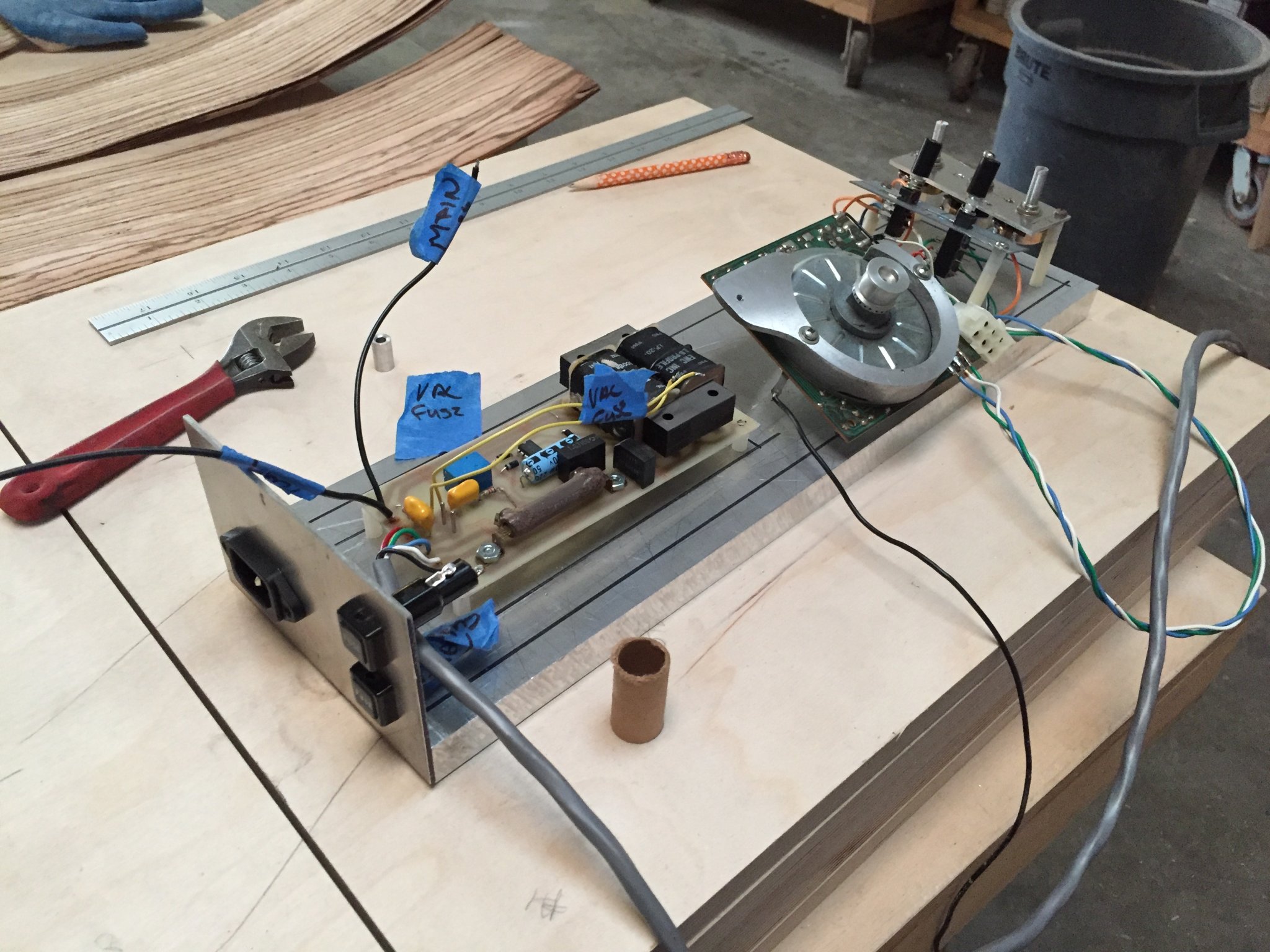

The motor and power supply were going into a smaller volume built up on a 3/4" 6061 aluminum plate that would all be enclosed in a birch ply box:

There was a lot of stuff to cram into the motor module:

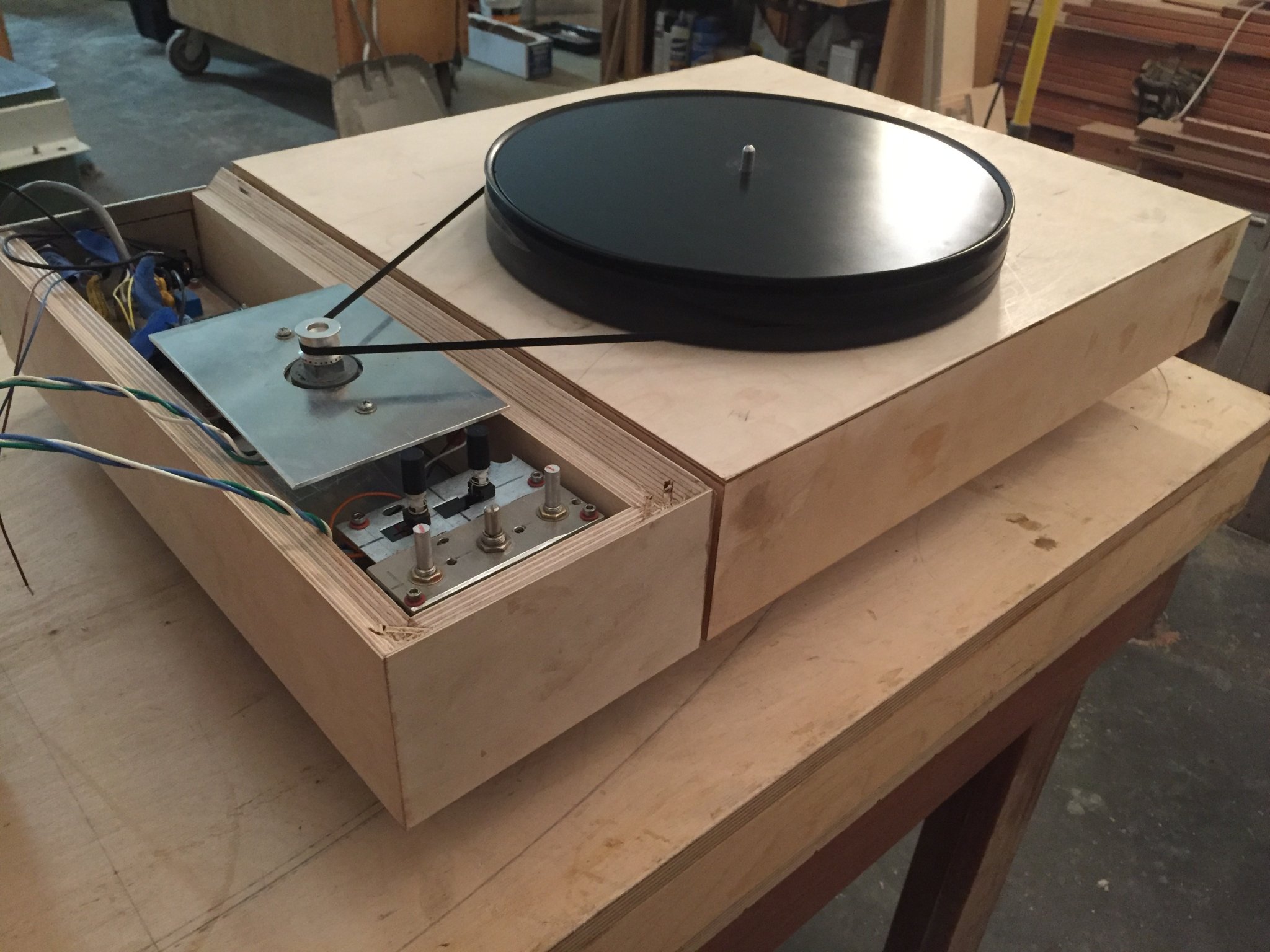

It started coming together like this:

The back of the motor module has an IEC receptacle for power in, A specialty connector for the vacuum power and control cable, and the fuses:

So the main platter and motor come together like this:

I had an abundance of this crazy hard south American hardwood from a commercial project I was building and I used that to make a 12" diameter cylinder for the vacuum module, and I found 10" diameter aluminum rem for the base.

Mass is one of the best things for damping noise and vibration, so Every bit of this rebuild added mass liberally.

The whole thing got veneered in a some really nice zebrawood...

A nice lacquer finish, and I set it up with two arms, my trusty SME mkVI arm and a new 12" Triangle Art Osiris magnetic bearing arm.

The finished deck is a huge upgrade from the original which was already a very good deck. After doing this I've been pondering building one from scratch and collecting parts to do so.

This is probably far more than you have in mind for your deck... A basic rebuild on that will involve replacing the suspension springs and rebalancing the the sub-platter. There's not a whole to those. They're pretty straight forward. You'll want the composite arm board. I might still have one if you're interested...

Thge sky's the limit though. The only limitations are time and budget. the rest is all imagination.

eso

And then in 2017 with the original vacuum pump seals dried out and failing and after making some custom parts for a new TT manufacturer I got a wild hair to do a major re-work. The new table was going to lose the suspended sub-chassis and be a very high mass rigid deck.

This happened:

I found a German company making a similar diaphragm type vacuum pump that was about twice the power of the original and decided on a heavy plinth with the platter, a separate module that would have the motor, power supply and controls with a very heavy vacuum module that could be placed way from everything else for the best isolation. The platter section is stacked Baltic Birch ply laminated to a 1" thick 6061 aluminum plate that the bearing would mount to.

The motor and power supply were going into a smaller volume built up on a 3/4" 6061 aluminum plate that would all be enclosed in a birch ply box:

There was a lot of stuff to cram into the motor module:

It started coming together like this:

The back of the motor module has an IEC receptacle for power in, A specialty connector for the vacuum power and control cable, and the fuses:

So the main platter and motor come together like this:

I had an abundance of this crazy hard south American hardwood from a commercial project I was building and I used that to make a 12" diameter cylinder for the vacuum module, and I found 10" diameter aluminum rem for the base.

Mass is one of the best things for damping noise and vibration, so Every bit of this rebuild added mass liberally.

The whole thing got veneered in a some really nice zebrawood...

A nice lacquer finish, and I set it up with two arms, my trusty SME mkVI arm and a new 12" Triangle Art Osiris magnetic bearing arm.

The finished deck is a huge upgrade from the original which was already a very good deck. After doing this I've been pondering building one from scratch and collecting parts to do so.

This is probably far more than you have in mind for your deck... A basic rebuild on that will involve replacing the suspension springs and rebalancing the the sub-platter. There's not a whole to those. They're pretty straight forward. You'll want the composite arm board. I might still have one if you're interested...

Thge sky's the limit though. The only limitations are time and budget. the rest is all imagination.

eso

Wow, thanks for sharing this! Love the idea of replacing the suspended plinth with high mass. For now I plan on a simpler rebuild and now that I have the platter bearing and motor taken care of I need to sort out the suspension. The plinth is dated in appearance but at least the wood on mine has a fairly simple grain along with the black Formica top. I wish I knew the spring rates so I could buy some aftermarket replacements, since the cost of springs through Sota is pretty steep.

You’ve seeded an idea that is hard to shake. I can manage the woodworking that you’ve done - did you fabricate the aluminum yourself?

You’ve seeded an idea that is hard to shake. I can manage the woodworking that you’ve done - did you fabricate the aluminum yourself?

Now you're asking me to remember things from a few years ago... I think I just went to my main metal supply house with measurements for what I was looking for and looked for rems that would work. I think I did have the supply house saw the plate for the power supply out of a larger rem and I used the fall from that for the bars for the motor mounting blocks.I can manage the woodworking that you’ve done - did you fabricate the aluminum yourself?

Sawing bars and thin sheets is easy with woodworking tools and the drilling a tapping is easy with any drill press. I think I even cut a 4" hole in the 1" plate in the main plinth for the SME arm cable.

Getting rid of the suspension dramatically improved the PRAT of the table. It's far livelier than an original.

Having started life as a SOTA Star, I've dubbed this one the Super Nova...

This is a cut sheet on the pump. You'll need to find a distributor for your area.Where did you find your replacement pump? Do you still have the arm board or other left over parts you no longer need?

https://www.schwarzer.com/en/gas-pumps/vibrating-diaphragm-pumps-sa/sp-300-sa-vd-ac

I probably have the composite arm board but I'll have to find it. The Board is drilled for an SME arm, so if you're using something other than one of their arms it might not be a good fit.

I'm pretty sure I don't have any other power supply parts or other items.

eso

Here's the SOTA Composite are board drilled for SME arms. I probably brought this in 2000-2001 direct from SOTA when i did first rebuild on the Star/Sapphire.I probably have the composite arm board but I'll have to find it

If one of you needs it, reach out to me...

eso

- Home

- Source & Line

- Analogue Source

- Sota Sapphire restoration project