Looking forward to getting some of these new boards!When I do a larger quantity order, I'll go for the extra bling ENIG (gold) finish.

Best,

Anand.

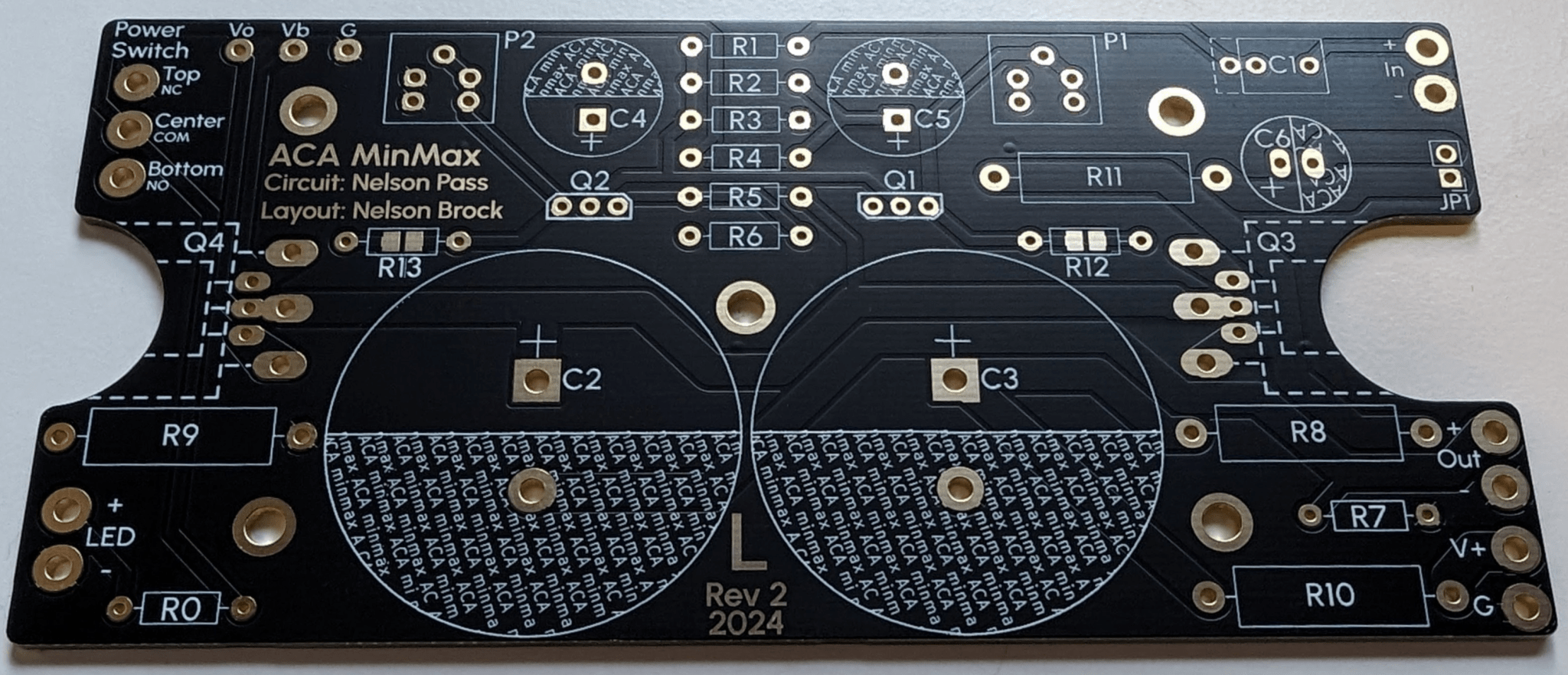

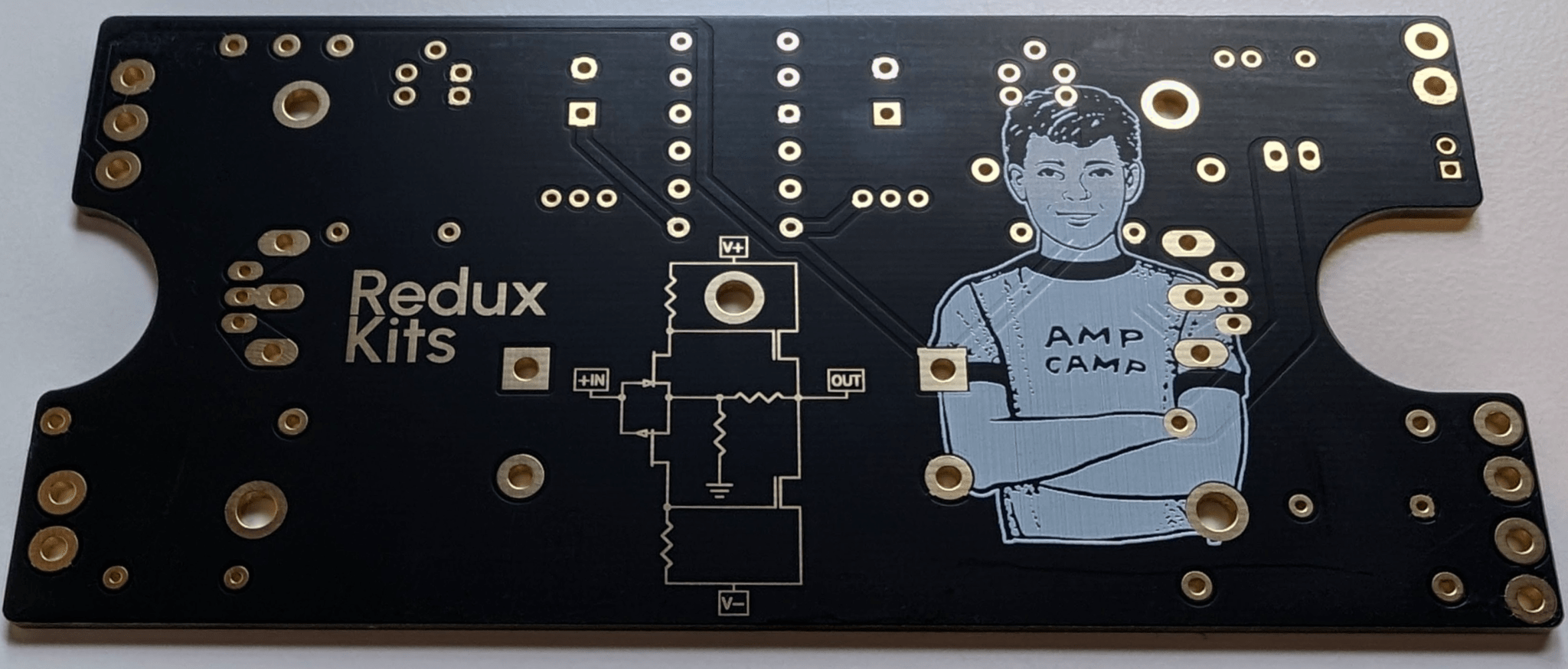

Good news for you both, here they are! I have 10 spare sets, private message me if you'd like one.

Just one functional change for rev 2: I reversed the connections to P1 and P2 to make the starting position before first power on and bias fully counterclockwise (like a volume control). On previous revisions, zero bias was fully clockwise.

I am also putting together a complete kit for the diyAudio store that will be bundled with the usual ACA chassis and a 36V power supply. A small test run first to work out any issues (Jason calls it a pioneer batch) then the goal is to keep it in stock as a regular product. This is my first time going through the store, so I don't know how long it will take for the listing to appear on the website. I'll share more info on the kits closer to when they become available but feel free to ask any questions you have now.

Just one functional change for rev 2: I reversed the connections to P1 and P2 to make the starting position before first power on and bias fully counterclockwise (like a volume control). On previous revisions, zero bias was fully clockwise.

I am also putting together a complete kit for the diyAudio store that will be bundled with the usual ACA chassis and a 36V power supply. A small test run first to work out any issues (Jason calls it a pioneer batch) then the goal is to keep it in stock as a regular product. This is my first time going through the store, so I don't know how long it will take for the listing to appear on the website. I'll share more info on the kits closer to when they become available but feel free to ask any questions you have now.

That's what I do with all trimmers in the PCBs that I draw up. Full counterclockwise on all trimmers before first power-up. Rotate clockwise after power-up for setup. Easy to remember.Just one functional change for rev 2: I reversed the connections to P1 and P2 to make the starting position before first power on and bias fully counterclockwise (like a volume control).

That is what I intended to do initially, but I assigned the schematic / footprint pinout incorrectly and didn't catch it until prototyping. I think this is where the issues in post #16 came from, had the pots all the way up when I thought they were all the way down.That's what I do with all trimmers in the PCBs that I draw up. Full counterclockwise on all trimmers before first power-up. Rotate clockwise after power-up for setup. Easy to remember.

I try to stay away from those by using triangle style footprints. Builder beware when substituting parts with alternative pinouts or footprints.How do you deal with the chuckleheads who have inline-pin trimmers [not triangle-of-pins trimmers] and install them upside down (rotated 180 degrees)

Not that I advocate the extra work, but I find placing the location of the trimmer adjustment screw on the silkscreen to be helpful in many cases. Example below.How do you deal with the chuckleheads who have inline-pin trimmers [not triangle-of-pins trimmers] and install them upside down (rotated 180 degrees) ?? You know, "If ya got it, use it!!" chuckleheads?

I've accumulated some experience with brilliantly unambiguous, "there's literally no way to interpret this wrong", PCBoards ... and chuckleheads. With great regularity a percentage of chuckleheads manage to install things bass-ackwards and then whimper "Help Me Obi-Wan I Don't Want To Think For Myself!! Study my photos and unFark my errors!"

^

Being 'one of those people' a.k.a. a chucklehead; at one point in life I found that trait to be highly valuable as a user-acceptance-tester for some in-house software.

If it could be broken; I found a way to break it. They loved it. I had found my home.

Being 'one of those people' a.k.a. a chucklehead; at one point in life I found that trait to be highly valuable as a user-acceptance-tester for some in-house software.

If it could be broken; I found a way to break it. They loved it. I had found my home.

Do realize that the pin configuration for lateral mosfets is different than vertical mosfets that this board is designed for and also that lateral mosfets have negative thermal coefficients instead of positive thermal coefficients.

There are other differences as well…

Best,

Anand.

There are other differences as well…

Best,

Anand.

OK! Got my boards, and an ACA Mini Essentials kit, power supply, and a F5M kit on the way as well, so time for a digikey order.

I see that folks have used both the original ACA Mini output devices (IRF9520/IRF520- with 0.75R degenerating resistors, perhaps?) and the larger IRFP9140/IRFP140 units (in the BOM with 0.47R degenerating resistors).

I like the idea of using the matched set of originals I got with the ACA Mini Essentials kit, but am concerned about heat depending on high I bias. What has been other folks experience with those?

If I were to order some IRFP9140/IRFP140 units, how many wold I likely need to find a good match, or is matching of the MOSFETs less important than I am assuming here? Or will I just be fine using the IRF9520/IRF520?

I see that folks have used both the original ACA Mini output devices (IRF9520/IRF520- with 0.75R degenerating resistors, perhaps?) and the larger IRFP9140/IRFP140 units (in the BOM with 0.47R degenerating resistors).

I like the idea of using the matched set of originals I got with the ACA Mini Essentials kit, but am concerned about heat depending on high I bias. What has been other folks experience with those?

If I were to order some IRFP9140/IRFP140 units, how many wold I likely need to find a good match, or is matching of the MOSFETs less important than I am assuming here? Or will I just be fine using the IRF9520/IRF520?

Last edited:

Regarding thermals:

I did some calculations when deciding what MOSFETs to include in the kits. I found many of these values online, so no guarantees for accuracy. To get from surface area to thermal resistance from case to heatsink, I'm assuming the isolating pads have 35 °C⋅mm²/W thermal impedance, which is in line with very good silpads or aluminum oxide + grease. I readjusted my MinMax when we had a few hot days in San Francisco last week and I landed on 850 mA / ch to achieve 60 °C heatsink temperature. At 36V power rails that's 30.6 W/ch, or 15.3 W/device.

Max junction temperature for most devices is 150 or 175 °C, so both the TO-220 and TO-247 parts are within their specifications at this power. The TO-220 parts run somewhat warmer and will warm up the interior of the chassis a bit more.

Capacitors are the only other real concern for temperature and they live fairly close to the transistors (and degenerating resistors), so I chose the the larger TO-247 parts for cooler running. I also find them easier to mount than TO-220 because of their flat top surface and insulated screw hole.

Ventilation is another factor I'm interested in that should influence how warm the inside of a chassis gets. I ran two tests, one with the top and bottom plates attached as normal, and one with the plates spaced off by 3mm using nylon M4 nuts (see pic). This gap increases the total ventilation area from 3600 mm² (slots only) to 6900 mm² (slots + gaps). With slots only, capacitor C3 measured 58 °C. With the gaps, the same capacitor measured 54 °C. A fairly minor difference, and no problem in either case for caps rated 85 °C. However, some supercaps (C6) that would otherwise be suitable have a 65 °C rating (like this one) so I chose this cap with an 85 °C rating for C6 in the kits.

I did some calculations when deciding what MOSFETs to include in the kits. I found many of these values online, so no guarantees for accuracy. To get from surface area to thermal resistance from case to heatsink, I'm assuming the isolating pads have 35 °C⋅mm²/W thermal impedance, which is in line with very good silpads or aluminum oxide + grease. I readjusted my MinMax when we had a few hot days in San Francisco last week and I landed on 850 mA / ch to achieve 60 °C heatsink temperature. At 36V power rails that's 30.6 W/ch, or 15.3 W/device.

| TO-220 | TO-247 |

Thermal resistance, Junction to case | 2.5 °C/W | 0.83 °C/W |

Surface area of interface | 44 mm² | 140 mm² |

Thermal resistance, Case to heatsink (= thermal pad impedance / area) | 0.79 °C/W | 0.25 °C/W |

Thermal resistance, Junction to heatsink (= junction to case + case to heatsink) | 3.3 °C/W | 1.1 °C/W |

Junction temperature at 15.3W (= thermal resistance × watts + 60°C heatsink temp) | 110 °C | 77 °C |

Case temperature at 15.3W (= thermal resistance × watts + 60°C heatsink temp) | 98 °C | 73 °C |

Max junction temperature for most devices is 150 or 175 °C, so both the TO-220 and TO-247 parts are within their specifications at this power. The TO-220 parts run somewhat warmer and will warm up the interior of the chassis a bit more.

Capacitors are the only other real concern for temperature and they live fairly close to the transistors (and degenerating resistors), so I chose the the larger TO-247 parts for cooler running. I also find them easier to mount than TO-220 because of their flat top surface and insulated screw hole.

Ventilation is another factor I'm interested in that should influence how warm the inside of a chassis gets. I ran two tests, one with the top and bottom plates attached as normal, and one with the plates spaced off by 3mm using nylon M4 nuts (see pic). This gap increases the total ventilation area from 3600 mm² (slots only) to 6900 mm² (slots + gaps). With slots only, capacitor C3 measured 58 °C. With the gaps, the same capacitor measured 54 °C. A fairly minor difference, and no problem in either case for caps rated 85 °C. However, some supercaps (C6) that would otherwise be suitable have a 65 °C rating (like this one) so I chose this cap with an 85 °C rating for C6 in the kits.

Attachments

The ACA Mini / MinMax does not require matching of the output MOSFETs.If I were to order some IRFP9140/IRFP140 units, how many wold I likely need to find a good match, or is matching of the MOSFETs less important than I am assuming here? Or will I just be fine using the IRF9520/IRF520?

I'll leave it up to you and the data above to decide between 520/9520 and 140/9140. What matters most is to build it according to your own preference.

- Home

- Amplifiers

- Pass Labs

- ACA MinMax - ACA mini retrofit for ACA chassis